Myth: Any outcome

between the customer specification limits considered as equal form the customer

perspective. For example customer queue time in a bank is between 15-30minutes,

as per this myth the customer who is been served at 15 minutes and another

customer at 30minutes is received the same quality from the bank perspective as

both of them are service within the agree time.

Reality: The

quality of service/ product will be of not equal from the customer/ society

perspective as it goes away from the target value even though it is within the

agreed specification limits.

Justification:

Taguchi one of the well-known statistician / engineer developed a

representation that measures the financial impact of loss to the society if the

product/service deviates from the target value. The representation is termed as

Taguchi’s Loss Function. In conventional methods the Cost of Quality is

measured considering the number of products rejected or reworked. In this

method it is difficult to differentiate the cost of quality if the two products

properties are within the specification limits but vary from each other.

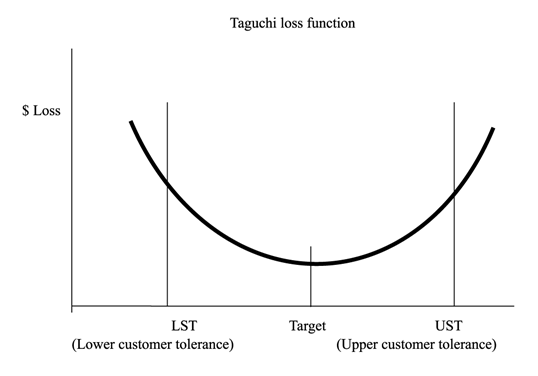

From Taguchi’s perspective the loss function is as below.

The graph depicts the lross function as a deviation from the target value of a

product parameter. The parameter could be a diameter, color, density, hardness

any other critical parameter of a product. From the service perspective the

parameter could be cycle time, communication, responsiveness etc.

UST – Upper Specification Tolerance, LST – Lower

Specification Tolerance

Taguchi believes performance begins decreasing gradually as

the design parameter deviates from the target value even though the parameter

value is between the LST and UST. Therefore, Taguchi proposed that the

loss function be measured by the deviation from the target value. The loss

function is

L = K * (Y – M) ^ 2

·

L is the result value of the function, generally

measured in monetary units

·

Y measured value

·

M target value

·

K is a loss coefficient (Convert into monetary

values)

Example: A company produces a part that has a diameter of 0.5

inches + or - 0.01 inches of tolerance. Failure cost of a rejection is $45.00.

There are 30 units produced and the actual diameter is as below. Calculate and

compare the loss considering the convention method as well as Taguchi’s loss

function method.

No comments:

Post a Comment