Showing posts with label RCA. Show all posts

Showing posts with label RCA. Show all posts

Tuesday, July 1, 2014

Monday, June 30, 2014

Six Sigma – Root Cause Analysis (RCA)

Introduction: Beneath

every problem there is an underlying cause but we need to identify the root

cause to prevent the recurrence. Many times the actions taken to address the

issue reoccur again in the same place or in a different place. This symptom indicates

that the root cause is not been identified/addressed. Root Cause Analysis (RCA)

is a structured approach for identifying and eliminating the underlying root

causes. It may not be feasible or necessary to conduct RCA for all the issues

as it involves time and effort. RCA is an analytical tool to perform a

comprehensive, system-based review of critical incidents. Primary objectives of

RCA includes

·

The

primary aim is to identify the root cause(s) and prevent that problem from ever

recurring

·

Systematic

way of approaching and resolving the problem

·

Prevent

the recurrence at lowest cost in the simplest way

- Define the

problem

- Gather the

information

- Plan for

Root Cause Analysis

- Conduct RCA

- Develop the

solutions and action plans

- Manage the

Action items

Labels:

Consulting,

Green Belt,

Improvements,

Lean,

RCA,

Six Sigma,

Statistics

Six Sigma – Root Cause Analysis Techniques

Many techniques available in conducting Root

Cause Analysis, each technique has its own advantages and suitable for a

particular situation. Common, widely accepted and simple to use techniques

includes

·

Cause & Effect diagram

·

5-Why Analysis

·

Brainstorming

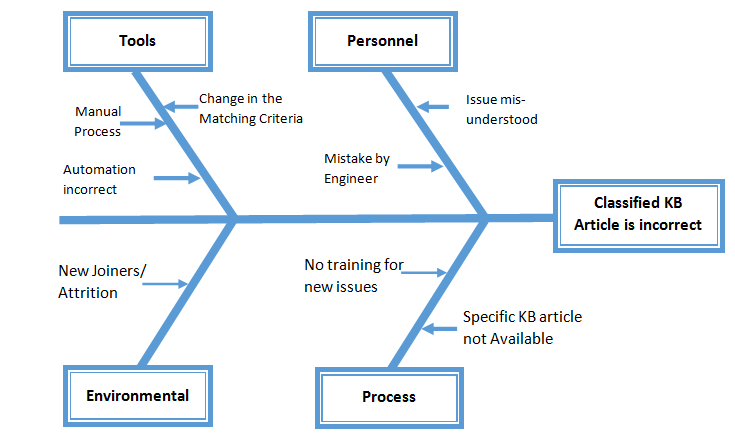

Cause &

Effect Diagram: Also

called as Fishbone diagram. This is a tool for identifying all the causes of an

effect. The effect being examined is the problem/opportunity that has to be

eliminated. C&E Diagram is a graphical representation of the causes and

effect. Use this technique for

·

Multiple causes has to be grouped logically

·

Understand width and depth of the causes

·

Problem is repetitive

Steps:

·

Write down the effect to be investigated and

draw the backbone arrow (as below)

Note: KB Article – Knowledge Base Article

has to be selected by the engineer to resolve an issue reported by the

customer. Selecting of wrong article either delays the resolution or

unnecessary escalation to a next level as the issue is unresolved by the engineer.

· Brainstorm with the identified people

considering all the broad areas/ groupings of the potential causes of the

effect “Classified KB article is incorrect”. Rule of thumb consider the generic

4 categories i.e., Man, Method, Material and Environment. You can define your

own categories and may use affinity diagram to group the cause.

·

Group the causes identified during the

brainstorming into logical groupings to represent the Cause & Effect

relationship.

·

Drill Down all the causes for further reasons

and goon extending the branches till the root cause is identified (May use

5-Why technique as required)

Five – Why

Analysis: 5-Why is a

problem solving technique that allows us to reach the root cause by repeatedly

asking the questions. Even though this technique is called “5-Why” we may reach

the root cause with fewer or more than five questions. Use this technique

·

Repetitive

issue without any supporting data

·

Simple

and low risk problems that does not require significant analysis

·

Problem

is very specific to a process/ system (Not spread to multiple processes)

Steps:

·

Define

the problem

·

Gather

the team and confirm the problem

·

Ask

the first Question Why? Record all the answers on a whiteboard or flipchart

·

Ask

few more successive “Why” until we reach no further causes

·

Confirm

the root cause and proceed for next set of actions

Example: Customer complaints on the delay in Pizza delivery

·

Why there is a delay

in the Pizza delivery?

o Delivery boy not reached on time

·

Why the delivery boy

not reached on time?

o He could not find the address

·

Why he could not find

the address?

o Address given to him is incorrect

·

Why the address is

incorrect?

o Address is not available in the records

·

Why the address is

not available in the records?

o Customer is new, manually note down the address

·

Why the address is

incorrect?

o Incorrectly noted while taking orders

Solution: Incase of the first

time users, confirm the address once again and provide the telephone numbers to

the delivery boy to reach out to the customer in case of any issues.

Brainstorming: One

of the very widely used and easy to use techniques for analyzing the problem to

reach the root causes. Brainstorming generates ideas and later evaluated to finalize

and confirm the causes.

Steps:

·

Establish

a clear objective, Re-phrase for confirmation

·

Create

a list of questions

·

Document

all the findings and agree on the same

Labels:

Consulting,

Green Belt,

Improvements,

Lean,

RCA,

Six Sigma,

Statistics

Subscribe to:

Posts (Atom)