Showing posts with label Lean. Show all posts

Showing posts with label Lean. Show all posts

Thursday, January 28, 2016

Tuesday, September 23, 2014

Tuesday, July 1, 2014

Six Sigma - Levels of Root Cause Analysis

Labels:

Green Belt,

Improvements,

Lean,

RCA,

Six Sigma,

Statistics

Monday, June 30, 2014

Six Sigma – Root Cause Analysis (RCA)

Introduction: Beneath

every problem there is an underlying cause but we need to identify the root

cause to prevent the recurrence. Many times the actions taken to address the

issue reoccur again in the same place or in a different place. This symptom indicates

that the root cause is not been identified/addressed. Root Cause Analysis (RCA)

is a structured approach for identifying and eliminating the underlying root

causes. It may not be feasible or necessary to conduct RCA for all the issues

as it involves time and effort. RCA is an analytical tool to perform a

comprehensive, system-based review of critical incidents. Primary objectives of

RCA includes

·

The

primary aim is to identify the root cause(s) and prevent that problem from ever

recurring

·

Systematic

way of approaching and resolving the problem

·

Prevent

the recurrence at lowest cost in the simplest way

- Define the

problem

- Gather the

information

- Plan for

Root Cause Analysis

- Conduct RCA

- Develop the

solutions and action plans

- Manage the

Action items

Labels:

Consulting,

Green Belt,

Improvements,

Lean,

RCA,

Six Sigma,

Statistics

Six Sigma – Root Cause Analysis Techniques

Many techniques available in conducting Root

Cause Analysis, each technique has its own advantages and suitable for a

particular situation. Common, widely accepted and simple to use techniques

includes

·

Cause & Effect diagram

·

5-Why Analysis

·

Brainstorming

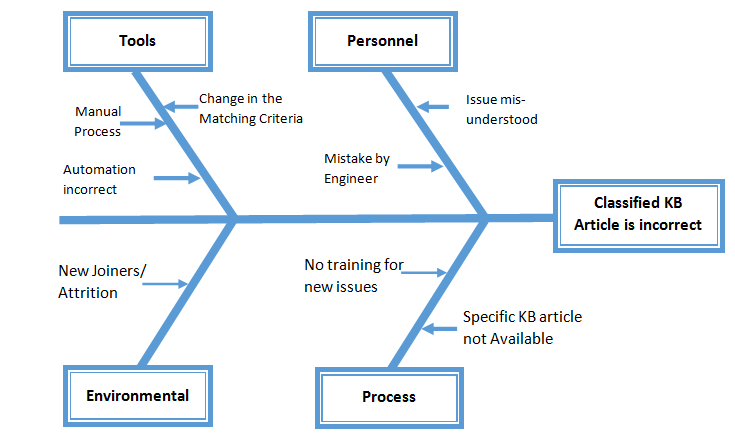

Cause &

Effect Diagram: Also

called as Fishbone diagram. This is a tool for identifying all the causes of an

effect. The effect being examined is the problem/opportunity that has to be

eliminated. C&E Diagram is a graphical representation of the causes and

effect. Use this technique for

·

Multiple causes has to be grouped logically

·

Understand width and depth of the causes

·

Problem is repetitive

Steps:

·

Write down the effect to be investigated and

draw the backbone arrow (as below)

Note: KB Article – Knowledge Base Article

has to be selected by the engineer to resolve an issue reported by the

customer. Selecting of wrong article either delays the resolution or

unnecessary escalation to a next level as the issue is unresolved by the engineer.

· Brainstorm with the identified people

considering all the broad areas/ groupings of the potential causes of the

effect “Classified KB article is incorrect”. Rule of thumb consider the generic

4 categories i.e., Man, Method, Material and Environment. You can define your

own categories and may use affinity diagram to group the cause.

·

Group the causes identified during the

brainstorming into logical groupings to represent the Cause & Effect

relationship.

·

Drill Down all the causes for further reasons

and goon extending the branches till the root cause is identified (May use

5-Why technique as required)

Five – Why

Analysis: 5-Why is a

problem solving technique that allows us to reach the root cause by repeatedly

asking the questions. Even though this technique is called “5-Why” we may reach

the root cause with fewer or more than five questions. Use this technique

·

Repetitive

issue without any supporting data

·

Simple

and low risk problems that does not require significant analysis

·

Problem

is very specific to a process/ system (Not spread to multiple processes)

Steps:

·

Define

the problem

·

Gather

the team and confirm the problem

·

Ask

the first Question Why? Record all the answers on a whiteboard or flipchart

·

Ask

few more successive “Why” until we reach no further causes

·

Confirm

the root cause and proceed for next set of actions

Example: Customer complaints on the delay in Pizza delivery

·

Why there is a delay

in the Pizza delivery?

o Delivery boy not reached on time

·

Why the delivery boy

not reached on time?

o He could not find the address

·

Why he could not find

the address?

o Address given to him is incorrect

·

Why the address is

incorrect?

o Address is not available in the records

·

Why the address is

not available in the records?

o Customer is new, manually note down the address

·

Why the address is

incorrect?

o Incorrectly noted while taking orders

Solution: Incase of the first

time users, confirm the address once again and provide the telephone numbers to

the delivery boy to reach out to the customer in case of any issues.

Brainstorming: One

of the very widely used and easy to use techniques for analyzing the problem to

reach the root causes. Brainstorming generates ideas and later evaluated to finalize

and confirm the causes.

Steps:

·

Establish

a clear objective, Re-phrase for confirmation

·

Create

a list of questions

·

Document

all the findings and agree on the same

Labels:

Consulting,

Green Belt,

Improvements,

Lean,

RCA,

Six Sigma,

Statistics

Monday, June 23, 2014

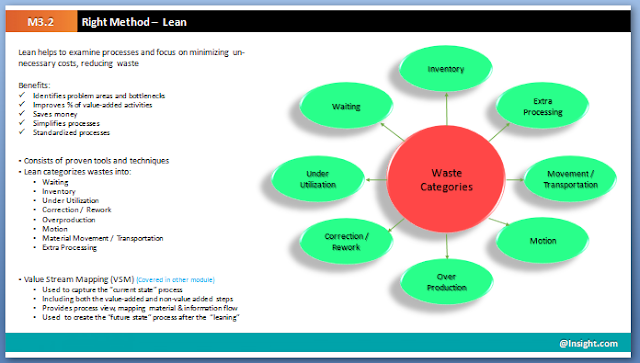

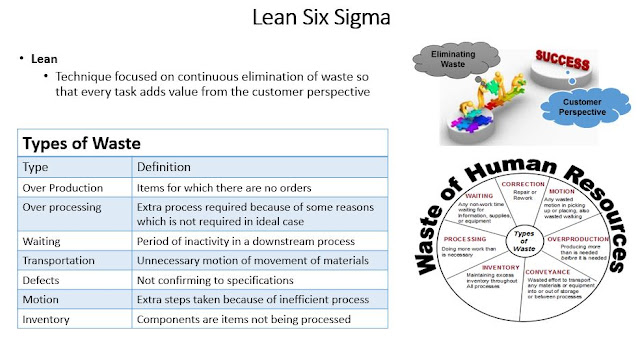

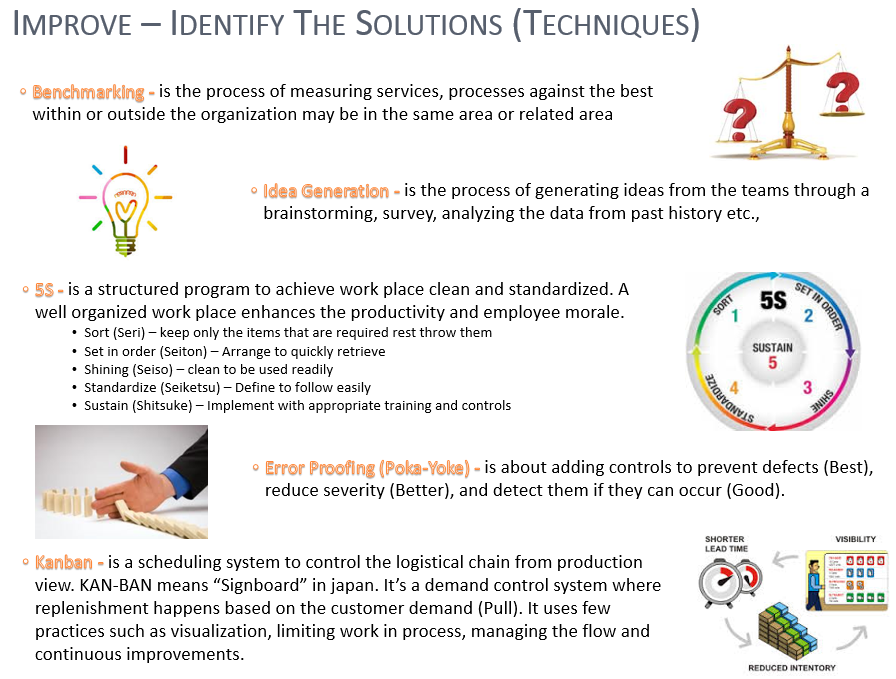

Lean – Tool Box

Below list

contains the list of tools used in Lean

· Value Stream Maps (VSM)

o

Visually map

the flow of production

o

Current and

future state of processes highlighting opportunities of improvement.

o

Exposes

waste in the current processes and provides a roadmap for future state

o

categorizes activities into three segments: value enabling, value

adding and non-value adding

o

Value enabling activities, however, cannot be totally eliminated

from a system

o

focus of this tool is on identifying and eliminating the non-value

added activities in each process step

·

Takt time

o

Takt time is

the rate at which a completed project needs to be finished in order to meet

customer demand

o

This is

the "heartbeat" of the customer

o

Takt =

T/D

§

Where T is

Time available for product/service.

§

D is a

demand for the number of units

§

T gives

information on production pace or units per hours

·

5S

o

Used to

organize the work area and eliminates the waste that results from poorly

organized work area.

§

Sort –

Eliminate that items that are needed

§

Set in order

– Organize the items that are needed

§

Shine –

clean the items

§

Standardize

– defined standard operating procedures

§

Sustain –

Regular compliance and improvement with respect to standards

·

Pull / Kanban

o

Regulating

the flow of goods using the signal cards as needed

o

Eliminates

inventory and overproduction

·

Spaghetti chart

o

Graphical

technique used mostly in lean manufacturing

o

Used to

display the actual flow/layout/material/machines and distances in a work

process

o

Poorly laid

out process work area that looks like a mass of cooked spaghetti

o

Used to

track work item flow, material flow and people flow

·

·

Poka – Yoke

o

Design the

process to detect, fix and prevent the defects as and when it happens

o

Cost of

fixing the defects increases exponentially as the work progresses and the

defects found in later stages than where they got injected

o

Also called

mistake proofing

·

SMED Single Minute Exchange of Die

o

Reduces the

time to Set up

o

Converting

the setup steps to external and simplifying the internal steps

o

Eliminating

non-essential steps and standardizing the work instructions

·

Total Productive Maintenance

o

A holistic

approach focuses on proactive and preventative

o

Empowering

operators to help maintain their equipment.

o

Shared

responsibility for equipment by plant floor workers

·

Heijunka

o

Production

scheduling that purposely manufactures in much smaller batches

o

System of

production designed to provide a more even and consistent flow of work

o

Reduces lead

times and inventory

·

Gemba

o

It’s a

philosophy that encourages to go to the work area and observe for any

opportunities than sitting in the closed cabins

o

Promotes

fist hand observations from the floor employees

·

Hoshin Kanri

o

Align

strategy (Top management) to tactics (middle management) to Actions (employees)

o

Continuity

towards goals by eliminating poor communication & improper direction

·

Jidoka

o

Design the

equipment’s to automate some part of the manufacturing process i.e. partial

automation is less costlier than full automation

o

Mainly focus

on avoiding/detecting and fixing defects quickly

·

Just in time (JIT)

o

Pull the

parts based on the customer demand instead of pushing the parts based on the

projections

o

Reduced the

inventory levels and reduces the space requirements

·

Kaizen

o

Regular and

incremental improvements

Friday, June 20, 2014

Six Sigma – Quadrant Analysis

This approach used to prioritize

the appropriate areas that are to be focused based on the identified criteria.

This technique is recommended when you have many items and you have to

prioritize few based on multiple criteria.

The example being used here

includes a set of issue categories being resolved by the team. Team needs to

prioritize the issues to be focused based on the below criteria

· - Volumes

· - Average Hold time/ Dependency time

· - Cycle time

o

Mean

o

Standard deviation

Approach being used is called as

Quadrant analysis. In this analysis the data is divided into 4 blocks based on

the volume and average hold/dependency time.

From the quadrant analysis the

team can prioritize the list of issues to be focused on considering the

multiple criteria as identified. This tool can be used in either Analyze/

Improve phases of six sigma projects where the team has to choose few out of

many with multiple criteria in hand. Also on the positive side the same can be

used to understand the best performers, applications, locations etc.

Thursday, June 19, 2014

Lean Tools - Value Stream Mapping (VSM)

Purpose:

•

Value stream mapping is used to identify the

value added / Non value added tasks in a process

•

Value is defined with respect to the end user

only

•

Special type of flow chart with additional

symbols to represent the waste/ flow / information

•

Overall objective of VSM analysis to reduce the

contribution of non-value added activities in the process from the customer

point of view

Steps

•

Identify the team and the process to be studied

for the VSM

•

Define the process workflow (As is process map)

using the predefined symbols used in VSM

•

Calculate the takt time, work time and lead

time (i.e., lead time includes work time

+ delay)

•

Classify / identify the non-value adds i.e.,

waste in the process

•

Define the future value stream map (to be

process map)

•

Identify the actions necessary to remove/reduce

the waste towards future VSM

Tips

•

Value should be always categorized from the end

user/ customer point of view only

•

Identify even a small step that can be done

while defining the as is process

Example: Below workflow shows the common process followed for

resolving a ticket from the issue reported to issue resolved. Even though this

process at high level is same but for a few types of issues the end to end

cycle time is high.

Subscribe to:

Posts (Atom)